- uArm xArm 6 Robotic Arm

- Is designed with multiple axes, perfect for repetitive tasks

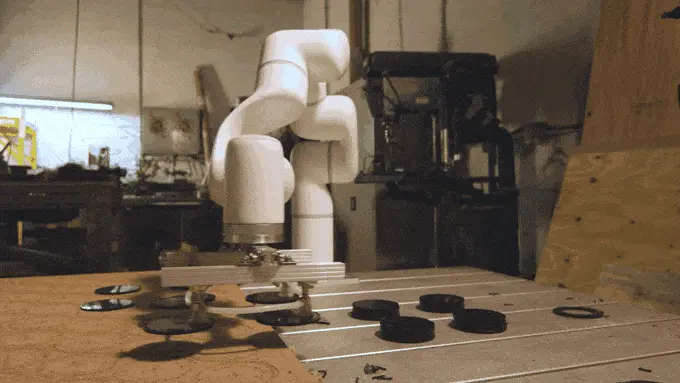

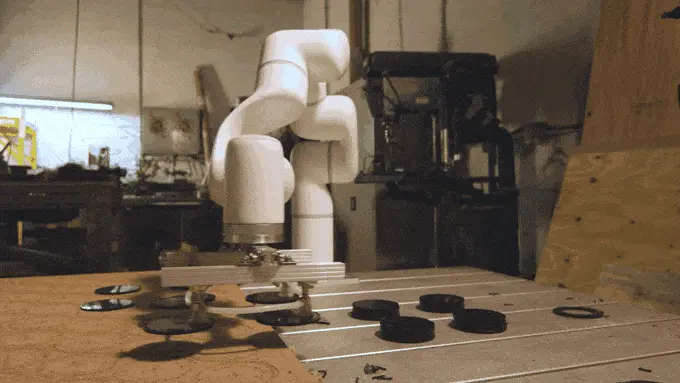

- Can operate your machines accurately

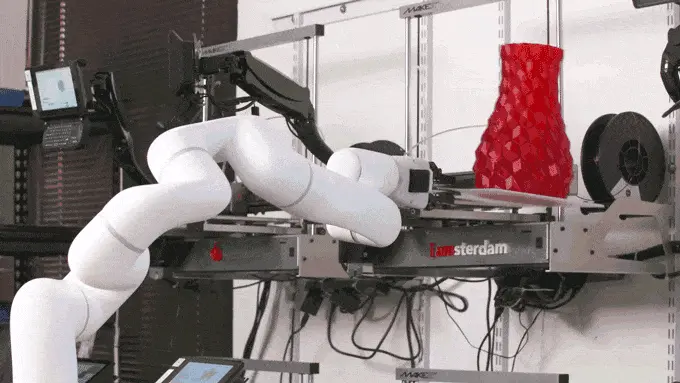

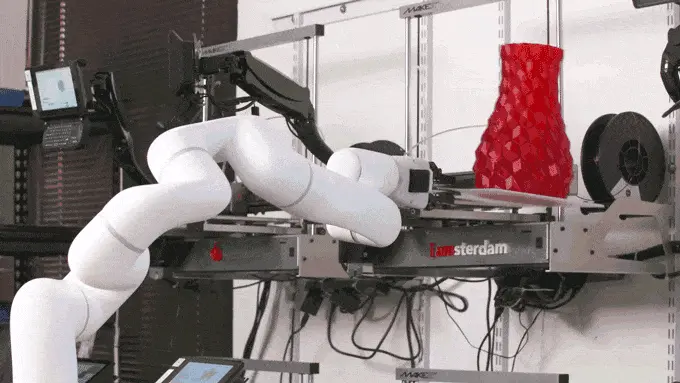

- Automatically unloads the objects from the printer immediately

- Has a payload of 5 kg and repeat-ability of 0.1 mm

- Can be widely used especially for pick-n-place task

The uArm xArm 6 Robotic Arm is created to aid manufacturing systems that allow for leaps forward in labor productivity performance. With xArm, your productivity will improve by over 95%, and the investments spent are quickly earned back by decreased labor costs and increased in production.

Instead of hiring people to tend to your machines, where its prone to human error, the xArm’s highly calculated precision hardware design can operate your machines accurately. Once a 3D printer finish printing, the xArm detect it with its computer vision system and automatically unload the objects from the printer immediately.

With the computer vision system of xArm, the robotics research will be much easier. Ufactory has cooperated with Intel to offer you a reliable solution and you can simply program the xArm with the open SDK.

xArm overthrows the traditional robotic arm design with its stylish and sophisticated look, with its sleek carbon-fiber structure and it adds a sense of style and freshness to your workplace. xArm features compact powertrain joint*. The customized outer rotor brushless motor combined with the built-in harmonic drive and 17 bit multi-turn encoders, creates high gear ratios, plus high torque capability, and delivers excellent repeatability, when repositioning inertial loads.

xArm 6 has a payload of 5 kg and repeat-ability of 0.1 mm, it delivers increased dexterity and flexibility, not to mention it is the best deal you can ever get among similar products on the market. The xArm is designed for small to mid-sized businesses with its best standard harmonic drive reducer, yet competitive pricing. xArm’s innovative features offers you a competitive advantage with guaranteed manufacturing excellence.

Unlike the industrial-grade robotic arm which is heavy and bulky to move around, xArm is lightweight and user-friendly, the handy and fast setup allows you to apply it to any process and in different setting. xArm features a universal tool mount port which allows users to install different head tools according to their needs. You can easily add the most commonly used end-actuators: a gripper, a vacuum system, and a camera module (sold separately) to help in various tasks.

If a shortage of advanced engineering workers is slowing your progress, don’t despair. They have revolutionized the way to control robots with hands on experience. Simply teach xArm to move and it will repeat the path for you. No coding is required. By dragging - dropping the blocks, complex path can be done in 10 mins. xArm SDK includes Python SDK, ROS SDK and C++ SDK. A fully upgradable software platform that can grow in capabilities to make it a lasting and worthy long-term investment.